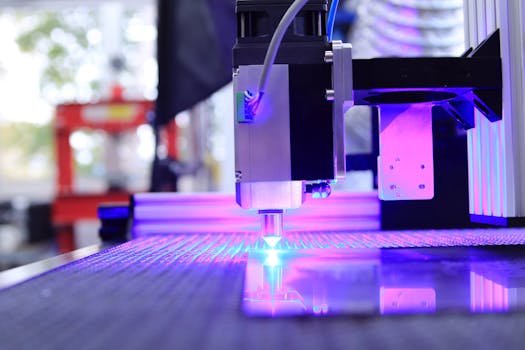

Ji haan, fiber laser se acrylic sheet cut kiya ja sakta hai. Agar aap naye hain ya is process ke baare mein soch rahe hain, toh yeh guide aapke liye hai. Aaj hum iske baare mein simple tarike se baat karenge.

Fiber Laser Acrylic Cutting Kaise Kaam Karta Hai?

Fiber laser ek concentrated light beam generate karta hai. Jab yeh beam acrylic sheet par padti hai, toh acrylic ka material vaporize ho jata hai, jisse ek clean cut line ban jaati hai. Ye process bohot precise hoti hai, jaise koi sharp pencil se line draw kar raha ho.

Fiber Laser se Acrylic Cutting ke Fayde

- High Precision: Fiber laser high precision ke sath acrylic ko cut karta hai. Isse aapko complex designs aur detailed shapes banaane mein aasani hoti hai.

- Smooth Edges: Is process se smooth edges wale cuts milte hain. Aapko cut ke baad extra sanding ya finishing ki zaroorat nahi padti, jo time bachata hai.

- Cost-Effective: Acrylic sheet cutting mein fiber laser ka istemal cost-effective bhi hota hai. Long run mein, yeh traditional cutting methods se sasta pad sakta hai kyunki isme tool wear nahi hota aur less waste produce hota hai.

- Fast Speed: Laser cutting bohot tez hota hai, jisse aap projects jaldi complete kar sakte hain.

Kya Dhyan Mein Rakhna Chahiye?

Dhyan rahe ki laser ki power aur settings sahi ho, taaki sheet sahi tarah se cut ho. Agar settings galat hain, toh acrylic melt ho sakta hai ya edges rough ho sakte hain. Shuruat mein, ek test piece par settings check karna acha idea hai.

Safety bhi important hai. Laser cutting se fumes nikalte hain, isliye proper ventilation ya exhaust system hona chahiye. Safety goggles pehnein taaki aapki eyes protect rahein.

Acrylic Cutting ke liye Basic Laser Settings

Yahan kuch general starting points hain. Aapke specific machine aur acrylic thickness ke hisaab se inko adjust karna hoga.

Material: Clear Acrylic (3mm)

Power: 45%

Speed: 15 mm/s

Frequency: 5000 Hz

Air Assist: ONYe settings ek approximate idea dene ke liye hain. Hamesha manufacturer ki guidelines follow karein aur apne material par test karein.

Fiber Laser vs. CO2 Laser for Acrylic

Donon lasers acrylic cut kar sakte hain, lehin kuch differences hain:

- Fiber Laser: Metal cutting ke liye excellent hai, lekin acrylic par bhi clean cut de sakta hai. Iski maintenance relatively kam hoti hai.

- CO2 Laser: Ye acrylic, wood, plastic jaise non-metal materials par cutting ke liye traditionally better mana jata hai. Isse acrylic par polished edge mil sakti hai.

Agar aap primarily acrylic aur similar materials kaam karte hain, toh CO2 laser better option ho sakta hai. Lekin agar aap metal bhi cut karte hain, toh fiber laser ek versatile choice hai. ThomasNet par CO2 vs Fiber Laser comparison padh sakte hain.

Acrylic cutting ke liye aur bhi tools available hain. Agar aap digital design se physical object banana chahte hain, toh humara Image to Text (OCR) Tool aapke sketches ko digital text mein convert karne mein madad kar sakta hai. Cutting se pehle, design ki dimensions check karne ke liye Aspect Ratio Calculator ka istemal karein.

Frequently Asked Questions (FAQs)

Kya fiber laser se colored acrylic bhi cut kar sakte hain?

Haan, lekin dhyan rahe. Clear aur white acrylic par fiber laser best results deta hai. Dark colored acrylic (jaise black) laser ki light ko absorb karta hai, jisse cutting process efficient hota hai. Lekin kuch bright colors laser beam ko reflect kar sakte hain, jisse cutting mushkil ho sakti hai. Hamesha test piece par try karein.

Acrylic cutting ke baad edges par flame polish kaise karein?

Flame polishing ke liye aapko propane torch ya specialized flame polisher ki zaroorat hogi. Edge ko gently heat karein taaki acrylic melt ho kar smooth surface bana le. Ye process delicate hai, practice ki zaroorat hoti hai taaki material burn na ho. Safety gear pehnein.

Laser cutting se nikalne wale fumes safe hain?

Nahi, acrylic laser cut karne par harmful fumes nikalte hain. Ye fumes irritate kar sakte hain aur long-term exposure harmful ho sakta hai. Isliye hamesha laser cutter ko well-ventilated area mein use karein ya isme attached exhaust/fume extraction system hona chahiye. Operator ko bhi proper mask pehnana chahiye.

Kya main apna design file khud bana sakta hoon?

Bilkul! Laser cutters generally vector files (jaise .SVG, .DXF, .AI) ko follow karte hain. Aap Photo Editor jaise free online tools use kar ke simple designs bana sakte hain. Ya phir Inkscape (free software) seekh sakte hain jo vector design ke liye acha option hai.