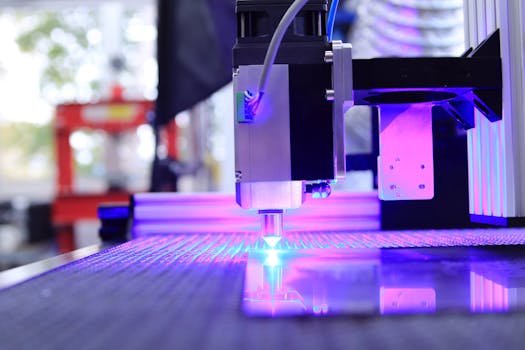

Acrylic sheet cut karne ke liye laser machine choose karna thoda confusing ho sakta hai. Aaj kal fiber laser aur CO2 laser dono popular hain, lekin dono ka kaam karne ka tareeka alag hai. Chaliye, simple shabdon mein samajhte hain ki aapke liye kaunsa sahi rahega.

Fiber laser ek solid-state laser hai. Isme cutting ka kaam ek "active fiber" ke through hota hai, jisko diodes pump karte hain. Ye machine infrared light produce karti hai, jo acrylic jaise materials ko absorb kar leti hai. Iska matlab hai ki fiber laser acrylic par focused energy deliver karta hai, jisse clean cut milta hai.

CO2 laser gas-based system hai. Isme carbon dioxide, nitrogen, aur helium ka mixture use hota hai. Jab is mixture mein electricity pass hoti hai, toh ye infrared light generate karta hai. Ye light acrylic ko efficiently cut kar sakti hai kyunki acrylic is wavelength ko acchi tarah absorb karta hai.

Acrylic Cutting ke Liye Comparison

Donon machines acrylic cut kar sakti hain, lekin performance aur results mein farak hai.

- Cutting Speed: Fiber laser generally faster hota hai. Agar aapko high-volume production chahiye, jaise din mein kayi pieces cut karne hain, toh fiber laser time bachayega.

- Edge Quality: CO2 laser acrylic par ek smooth, polished edge de sakta hai, jo directly cut karne par bhi shiny dikhta hai. Fiber laser bhi clean cut deta hai, lekin edge thoda different texture ka ho sakta hai, jisko baad mein flame polish karna pad sakta hai.

- Precision: Fiber laser ki beam bahut thin aur focused hoti hai, isliye intricate designs aur fine details ke liye ye behtar hai. CO2 laser bhi precise hai, lekin fiber ki tarah extreme fine detail mein utna sharp nahi ho sakta.

- Maintenance aur Cost: CO2 laser machines generally fiber lasers se sasti aati hain aur unki maintenance bhi relatively simple hoti hai. Fiber lasers mehenge hain, lekin unki operational cost kam hoti hai kyunki woh zyada efficient hain aur parts ko kam replace karna padta hai.

Practical Advice: Aapke Liye Kaunsa?

Yeh decide karne ke liye apne kaam ki zaroorat ko dekhiye.

- Fiber Laser Lein Agar: Aapka focus speed aur high precision par hai. Aapko complex shapes, bahut sare parts, ya fine text cut karna hai. Aap long-term par operational cost bachana chahte hain.

- CO2 Laser Lein Agar: Aapka budget limited hai. Aap sirf acrylic nahi, balki wood, leather, fabric jaise diverse materials bhi cut karna chahte hain. Aapko cut edge par high-gloss finish directly machine se chahiye.

Ek aur important baat: acrylic ki thickness bhi matter karti hai. Thicker acrylic sheets (10mm se zyada) cut karne ke liye CO2 laser behtar performance de sakta hai kyunki uski wavelength thicker material ko penetrate karne mein efficient hai.

Machine Type Initial Cost Running Cost Best For

-----------------------------------------------------------------

CO2 Laser Medium Medium Versatility, Glossy Finish

Fiber Laser High Low High-Speed, High-Precision ProductionFinal decision lene se pehle, agar ho sake toh apne material ka sample le kar dealer ke paas jaayein aur dono machines par test cut karwa ke dekhiye. Aankhon dekhne se aapko quality aur speed ka asli farak samajh aa jayega.

Laser cutting ke alawa, agar aap digital design ya image editing ka kaam karte hain, toh hamare Image Tools collection ka use kar sakte hain. Aur agar aap apne designs ko PDF mein save karna chahte hain, toh Image to PDF Converter kaam aa sakta hai.

Frequently Asked Questions (Aksar Puche Jane Wale Sawal)

Kya fiber laser se acrylic cut karte waqt harmful fumes nikalte hain?

Haan, kuch amount mein fumes bante hain, kyunki acrylic plastic hai. Isliye har laser machine ke saath proper exhaust aur ventilation system hona bahut zaroori hai, chahe woh fiber ho ya CO2.

Kya main ek hi machine se acrylic aur metal cut kar sakta hoon?

Fiber laser metal cutting ke liye behtar hai. CO2 laser acrylic, wood, plastic jaise non-metals par accha kaam karta hai. Agar aapko dono type ke materials regularly cut karne hain, toh aapko alag-alag machines ki zaroorat pad sakti hai.

Acrylic cutting ke liye konsi machine zyada popular hai?

Small businesses aur hobbyists ke beech CO2 laser zyada popular hai kyunki ye versatile aur cost-effective hai. Large-scale manufacturing units mein, jahan speed aur automation important hai, wahan fiber laser ka use badh raha hai. Aap industry ke trends ThomasNet jaise authentic sources se padh sakte hain.

Mujhe apne design files ko edit karna hai, koi simple tool hai?

Haan, aap hamare Photo Editor ka use kar sakte hain. Ye online tool aapko basic editing features deta hai jo laser cutting ke liye design banane mein madadgar ho sakta hai.