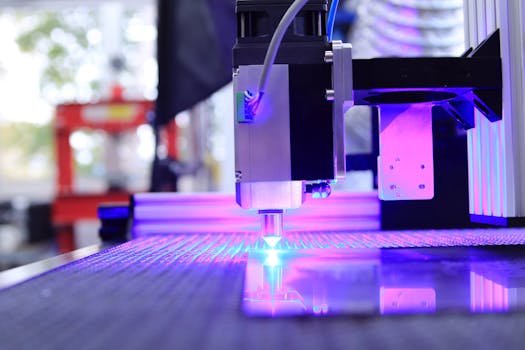

Haan, fiber laser cutting machines aksar cutting aur marking dono kaam karte hain. Socha jaaye to ye ek versatile tool hai jo metal, plastic, aur kai materials par precise kaam kar sakta hai.

Key Points

- Fiber laser machines high precision ke sath kaam karte hain. Matlab, jo design aap chahte ho, bilkul waisa hi cut ya mark milta hai.

- Ye chhote aur intricate designs ko bhi aasani se cut aur mark kar sakte hain. Jaise kisi machine part par serial number ya company logo.

- Ismein kam maintenance ki zarurat hoti hai compared to traditional cutting methods. CO2 laser ya plasma cutter ki tarah rozana tuning ki zarurat nahi padti.

- Ye fast aur efficient hote hain, jo production ko boost karte hain. Ek baari setup ho jaane ke baad, ye lagatar kaam karte rehte hain.

How Does It Actually Work?

Thoda technical side samjhte hain, simple bhasha mein. Fiber laser machine ek special type ka glass fiber use karti hai. Is fiber ke andar laser light generate hoti hai aur ek focused point par concentrate hoti hai. Jab ye intense light material ko touch karti hai, to material vaporize (gas ban jaata hai) ho jaata ya melt ho jaata hai, jisse cut ya mark ban jaata hai.

Iska ek bada fayda ye hai ki laser beam ko mirrors ki madad se easily guide kiya ja sakta hai, isliye cutting head ko material ke upar aasani se move karaya ja sakta hai complex shapes banane ke liye.

G21 ; Set units to millimeters

G90 ; Absolute positioning

M3 S1000 ; Turn laser on, set power

G1 X10 Y10 F500 ; Move to start position

G1 X50 Y10 ; Cut a straight line

G1 X50 Y50 ; Cut another line

G1 X10 Y50 ; Cut third line

G1 X10 Y10 ; Return to start (completing a square)

M5 ; Turn laser offYeh upar wala code ek simple square shape cut karne ke liye instructions hain. Aisi hi commands se machine ko bataya jaata hai kya design banana hai.

Cutting vs. Marking: Farak Kya Hai?

Donon processes laser use karte hain, par intention alag hai:

- Cutting: Yahan laser material ko poori tarah se through kar deti hai, pieces alag kar deti hai. Jaise sheet metal se koi part kaatna.

- Marking (Engraving): Yahan laser sirf material ki surface ko lightly alter karti hai, permanent text ya design chhod jaati hai bina material ko cut kiye. Jaise surgical instrument par branding karna.

Ek hi machine power aur speed adjust karke dono kaam kar leti hai. For more on creating designs for cutting, you can check out our SVG Editor tool.

Kis Cheez Par Use Kar Sakte Hain?

Fiber laser steel, aluminum, brass, copper jaise metals par bahut accha kaam karti hai. Kuch plastics par bhi use ki ja sakti hai. Par glass, wood, ya cloth par iska zyada effect nahi hota—unke liye CO2 laser behtar hoti hai.

Agar aap kisi product par permanent marking kar rahe hain, to aapko uski design ki high-quality image chahiye hogi. Aap humare Image to Vector Converter se apne logo ko laser-friendly format mein convert kar sakte hain.

Frequently Asked Questions

Fiber laser machine ki lifespan kitni hoti hai?

Achi tarah maintain karne par, ek fiber laser source 100,000 se zyada hours tak chalti hai. Ye CO2 laser se kai guna zyada hai. Regular maintenance mein lenses saaf karna aur cooling system check karna shamil hai.

Kya mai ghar par fiber laser machine use kar sakta hoon?

Nahi, ye industrial machines hain. Inhe chalaane ke liye 3-phase power supply, proper exhaust system (fumes ke liye), aur safety training ki zarurat hoti hai. Hobby ke liye smaller desktop laser engravers available hain.

Laser cutting ke liye design kaun se software mein banayein?

Aap industry standard software jaise AutoCAD, SolidWorks, ya CorelDraw use kar sakte hain. Free options mein Inkscape accha hai. Design ko akhir mein .DXF ya .SVG file format mein save karna hota hai jo laser machine samajh sake. Aap directly apna design check karne ke liye humare SVG Viewer tool ka istemal kar sakte hain.

Fiber laser safety precautions kya hain?

Sabse zaroori hai proper safety glasses pehanna jo specific laser wavelength ke liye designed hon. Machine enclosure band rakhna, fumes ko vent out karne ka system hona, aur emergency stop button accessible hona chahiye. Kabhi bhi laser beam ko directly mat dekhein.

Overall, fiber laser technology ne manufacturing industry ko bahut simplify kar diya hai, allowing for precise, fast, and repeatable results. Agar aap is field mein naye hain, to chhote projects se start karna behtar rahega. For calculating material costs or project dimensions, our Unit Converter might come in handy.