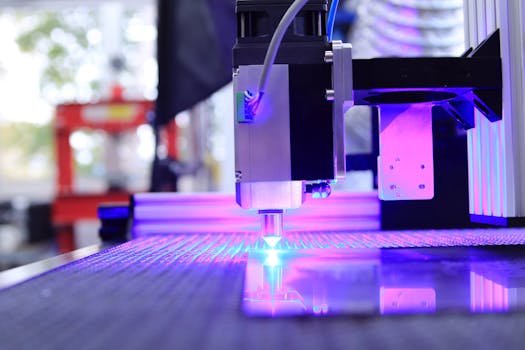

Yes, absolutely. A fiber laser is a very flexible tool that can do both jobs—marking and cutting—really well. Think of it like a multi-tool in your workshop. You can use it to etch a design onto a metal part and then, with a few adjustments, use the same machine to cut that part out.

Here’s a simple breakdown of how it works and why it's so useful.

How Does One Laser Do Two Jobs?

It all comes down to control. A fiber laser produces a very intense, focused beam of light. What you do with that beam depends on two main things:

- Power: How much energy you're putting into the beam.

- Focus: How tightly you concentrate that beam onto the material.

For marking (or engraving), you use lower power. The beam heats the surface just enough to change its color or create a shallow groove without going all the way through. It's like using a very hot pen to write on metal.

For cutting, you crank up the power and focus the beam into an extremely fine point. This concentrated energy melts or vaporizes the material along a precise path, cutting right through it.

The cool part is that modern fiber laser machines let you switch between these modes quickly, often within the same job file.

Why Choose a Fiber Laser for This?

Fiber lasers have become the go-to choice for many workshops because of a few key benefits:

- Precision & Speed: They are incredibly accurate and fast, perfect for detailed designs or high-volume production.

- Versatility: They can work on a wide range of materials—metals like steel, aluminum, and brass, as well as some plastics and ceramics.

- Cost-Effective: They are generally more energy-efficient and have fewer moving parts than older CO2 lasers, which means lower electricity bills and less maintenance over time.

- Long Lifespan: The fiber laser source itself is very durable and can last for tens of thousands of hours.

What Can You Make With It?

The applications are everywhere. You could use one machine to:

- Cut out custom-shaped machine parts and then mark them with serial numbers.

- Create intricate jewelry, cutting the shape and then engraving a pattern.

- Produce electronic components, cutting circuit board blanks and marking logos or codes.

- Make promotional items like metal business cards, cutting them to size and engraving the text.

If you're working with designs, our SVG Editor is a great tool to prepare your artwork before sending it to the laser.

Things to Keep in Mind

While fiber lasers are versatile, there are limits. They are best suited for metals. For cutting thick materials (like very heavy steel plate) or non-metals like wood or acrylic, a CO2 laser might sometimes be a better fit. Always check what material thickness and type your specific laser model is rated for.

For planning projects that involve measurements and scaling, tools like our Image Resizer or Unit Converter can be very handy.

Frequently Asked Questions

Can the same laser head do marking and cutting?

Yes, typically it can. The same laser head and beam delivery system is used for both processes. The machine's software controls the power, speed, and focus to switch between the two functions.

Do I need different software for marking and cutting?

Not usually. Most laser control software (like LightBurn or RDWorks) can handle both tasks in one project file. You can set some lines to be engraved at low power and other lines to be cut at full power, all in the same job.

Is it slower to use one machine for both jobs?

Not significantly. The switch between marking and cutting parameters happens almost instantly. The main time factor is the actual processing time for each operation, which is very fast with fiber lasers.

What materials work best for both marking and cutting with a fiber laser?

Metals are the ideal choice. Stainless steel, aluminum, brass, and titanium all mark (with a nice contrast) and cut beautifully with a fiber laser. Plastics can be trickier, as some may melt or produce harmful fumes.

In short, a fiber laser is a powerful and smart investment if you need to both mark and cut materials, especially metals. Its ability to handle multiple tasks with high precision makes it a central piece of equipment for modern manufacturing and fabrication.

For more tools that can help in your digital workshop, check out our full list of free online tools.