If you're looking into lasers for cutting, engraving, or marking, you've probably come across two main types: fiber lasers and CO₂ lasers. They might seem similar at first, but they work in very different ways and are good at different jobs. Let's break down how they're not the same.

How They Make the Laser Beam

The biggest difference is what's inside them and how they create the laser light.

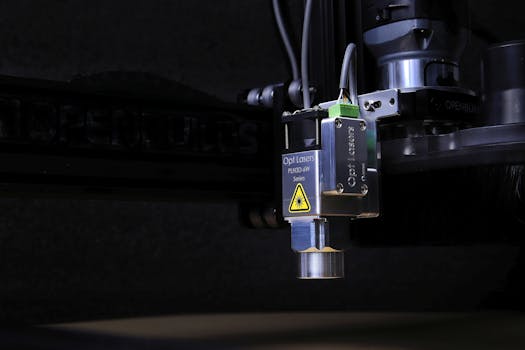

- Fiber Laser: Think of this like a super-powered fiber optic cable. It uses a special optical fiber doped with rare-earth elements (like ytterbium) as the "laser medium." The light is generated and travels right inside this fiber, which acts like a guide.

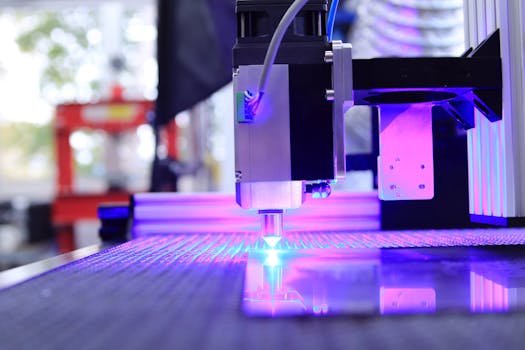

- CO₂ Laser: This type is more like a traditional glass tube. It uses a gas mixture (mainly carbon dioxide, with nitrogen and helium) as the laser medium. An electrical discharge excites the gas to produce the laser beam.

What They're Good At (The Wavelength)

This internal difference leads to a key practical difference: the wavelength of light they produce.

- Fiber Laser: Produces a wavelength around 1.06 micrometers (µm). This is a near-infrared wavelength.

- CO₂ Laser: Produces a much longer wavelength, around 10.6 micrometers (µm). This is in the far-infrared range.

Why does this matter? Different materials absorb different wavelengths of light better.

Key Points

- Fiber lasers use optical fibers for beam delivery, while CO₂ lasers use gas mixtures.

- Fiber lasers have higher electrical efficiency and better beam quality compared to CO₂ lasers.

- CO₂ lasers are typically better suited for cutting and engraving organic materials (like wood, acrylic, leather, glass, and some plastics), as their wavelength is highly absorbed by these materials.

- Fiber lasers excel at marking and cutting metals (like steel, aluminum, brass) and some plastics. Their wavelength is absorbed well by metals.

- Fiber lasers are more compact, have no mirrors to realign, and generally require less maintenance than CO₂ lasers, which have more complex gas systems and optics.

A Simple Comparison Table

| Aspect | Fiber Laser | CO₂ Laser |

|---|---|---|

| Laser Medium | Solid-state (Doped Optical Fiber) | Gas (CO₂, N₂, He Mixture) |

| Typical Wavelength | ~1.06 µm | ~10.6 µm |

| Best For | Metals, Marking, Some Plastics | Wood, Acrylic, Glass, Leather, Paper, Fabrics |

| Efficiency | High (often 25-30%) | Lower (typically 10-15%) |

| Maintenance | Generally Low | Higher (gas, optics, mirrors) |

So, it's not that one is "better" than the other. It's about choosing the right tool for your material. For a metal workshop, a fiber laser is often the go-to. For a sign maker using wood and acrylic, a CO₂ laser is usually the perfect fit.

If you're working with images or designs for laser cutting, you might need to prepare your files. You can check out our Image to Vector Converter to help get your designs ready.

Frequently Asked Questions

Can a fiber laser cut wood or acrylic?

It can, but not as effectively as a CO₂ laser. The 1.06 µm wavelength of a fiber laser is not absorbed as well by these organic materials, often resulting in charring or poor edge quality. A CO₂ laser is the standard choice for these materials.

Which laser is more expensive?

Historically, CO₂ lasers had a lower entry cost, but prices for fiber lasers have dropped significantly. When considering total cost, factor in electrical efficiency and maintenance. Fiber lasers often have a lower cost of operation over time due to their higher efficiency and lower maintenance needs.

Do I need special software to run them?

Both types use similar design and control software (like LightBurn or RDWorks). The main difference is in the machine driver that communicates the design to the laser. The core process of creating your design is largely the same. You can use our free SVG Editor to work on designs.

What does "beam quality" mean?

Beam quality refers to how well the laser beam can be focused to a tiny, precise spot. A higher quality beam (like from a fiber laser) means you can achieve finer details and sharper cuts, especially on metals. For more on precision tools, see our Unit Converter for calculations.