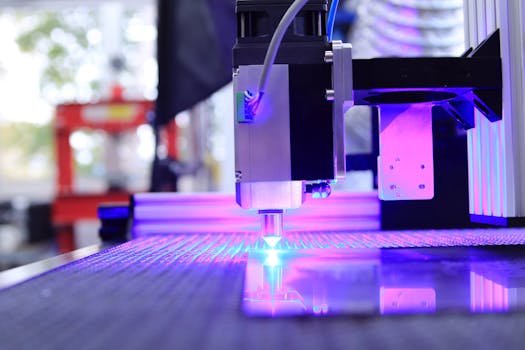

If you're new to working with fiber lasers, you might be wondering how long one lasts. It's a bit like asking how long a car engine will run—it depends on a lot of factors. A fiber laser source is the core component that generates the laser beam, and its lifespan is a key consideration for any project or business.

Typically, you can expect a well-made fiber laser source to last between 25,000 to 50,000 hours of operation. To put that in perspective, if you ran it 8 hours a day, every day, that's roughly 8 to 17 years of service. That's a pretty good run!

What Affects a Laser's Lifespan?

Just like any piece of equipment, how you use and care for it makes all the difference. Here are the main things that influence how long your laser will last:

1. The Quality of the Build

Not all lasers are created equal. A source built with high-quality components—like a robust pump diode and clean, pure optical fibers—will naturally last longer and perform more consistently than a cheaper model. It's often worth investing in a reputable brand.

2. Your Operating Environment

Lasers don't like extreme conditions. Keeping your laser in a clean, temperature-controlled, and vibration-free environment is crucial. Excessive heat, dust, or humidity can stress the internal components and shorten its life.

3. How Hard You Push It

Running the laser continuously at its maximum power output will cause it to wear out faster. It's similar to revving a car engine at its redline all the time. Using it within its recommended power range and giving it proper cooling cycles helps immensely.

4. Regular Maintenance

This is the biggest factor you can control. Simple, scheduled maintenance can prevent small issues from becoming big problems. This includes:

- Keeping optical connections clean.

- Checking and replacing cooling system filters.

- Monitoring power output for any unexpected drops.

Think of it like getting an oil change for your car—it's essential for long-term health.

How to Get the Most Out of Your Laser

Want to hit that 50,000-hour mark or beyond? Follow these practical tips:

- Follow the Manual: The manufacturer's guidelines are your best friend. They know the product best.

- Monitor Performance: Keep a log of power levels and error messages. A gradual decline can signal it's time for a check-up.

- Use a Good Power Supply: Protect your laser from electrical spikes and surges with a stable power source and maybe a surge protector.

- Train Your Team: Make sure everyone who operates the laser knows the basics of proper use and daily checks.

When Should You Plan for a Replacement?

Even with great care, components age. Start planning for a replacement if you notice:

- A significant and irreversible drop in output power.

- Increased instability in the beam quality.

- More frequent errors or required maintenance.

Proactive planning is better than an unexpected breakdown that stops your work.

Frequently Asked Questions

Is the 25,000-50,000 hour lifespan a guarantee?

No, it's an average estimate under normal operating conditions. Think of it as a typical mileage expectation. Your actual results will depend on the factors we discussed like maintenance, environment, and usage.

Can a fiber laser be repaired if it fails?

Sometimes, yes. Common wear items like pump diodes or cooling fans can often be replaced by a technician. However, if the core optical fiber is damaged, it might be more cost-effective to replace the entire source module. Always consult with the manufacturer or a certified service provider.

What's the biggest mistake that shortens laser life?

Neglecting basic maintenance and ignoring the operating environment. Letting dust build up on optics or running the laser in a hot, dirty shop are surefire ways to reduce its lifespan significantly.

Where can I learn more about maintaining my equipment?

Your first stop should always be the official manufacturer's documentation. For general best practices on equipment care and maintenance schedules, you can find helpful guides on sites like Machine Design or Thomasnet. For specific laser power and efficiency calculations, you might find tools like our own Compound Interest Calculator useful for projecting long-term operational costs, though it's for a different purpose!